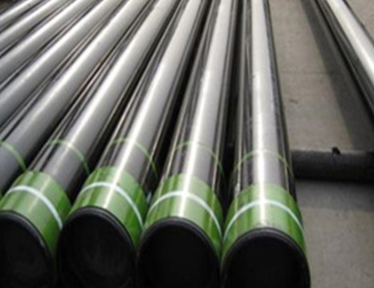

The concept of oil casing: Oil casing is a special type of pipe used for earthquake resistance. They are often used in earthquake-prone areas to prevent damage to oil facilities from earthquakes. The main function of oil casing is to protect oil pipeline from earthquake. These special pipelines have strong durability and can effectively reduce the damage caused by earthquakes to oil transportation facilities. The use of oil casing can significantly reduce the downtime caused by earthquakes, while also ensuring personnel safety. In addition, the use of these special pipes can also reduce the impact of earthquakes on the surrounding environment.

Oil casing manufacturing method: The seismic effect of oil casing is very strong, because the material of oil casing itself has a high strength. In addition, the manufacturing method of oil casing is also important. Oil casing is usually formed by high pressure forging, which can make it have better shock resistance. In addition, the surface is specially treated during the manufacturing process to make it more wear-resistant and corrosion-resistant. In short, because the oil casing material itself has high strength and durability, it has a strong seismic effect.

Seismic effect of oil casing: Oil casing refers to a special pipeline designed to protect oil pipelines. It has the ability to prevent the transmission of pressure waves caused by earthquakes and other geological movements to oil pipelines. This allows the oil fluid to run smoothly under earthquake conditions and ensure normal use. With the passage of time, people’s understanding of earthquakes has also improved, and there are new requirements for how to construct buildings with good earthquake resistance. As an important infrastructure, oil casing should also have good seismic performance. In view of this problem, the related research work is also gradually launched. Recently, a group of researchers from Tohoku University and Hokkaido University in Japan conducted a detailed test and analysis of oil casing made of various materials currently used, and made some concrete recommendations. According to their experimental results, there is a significant difference in the energy absorption of tubes made of different materials. Considering the relative cost, they believe that the use of composite materials for casing is a wise choice. In addition, according to the experimental data, it can be concluded that in order to ensure its seismic performance, the casing should be as large and strong as possible. Therefore, in practical applications should try to use large caliber, thick wall sleeve.